Plastic injection molding is one production method that has become progressively more crucial in California’s industrial scene. This technique is used extensively to generate a great variety of plastic goods ranging from automotive components to medical equipment. Knowing the importance of Plastic Injection Molding in California not only highlights it but also helps businesses and manufacturers realize the possibilities it presents.

What is Plastic Injection Molding?

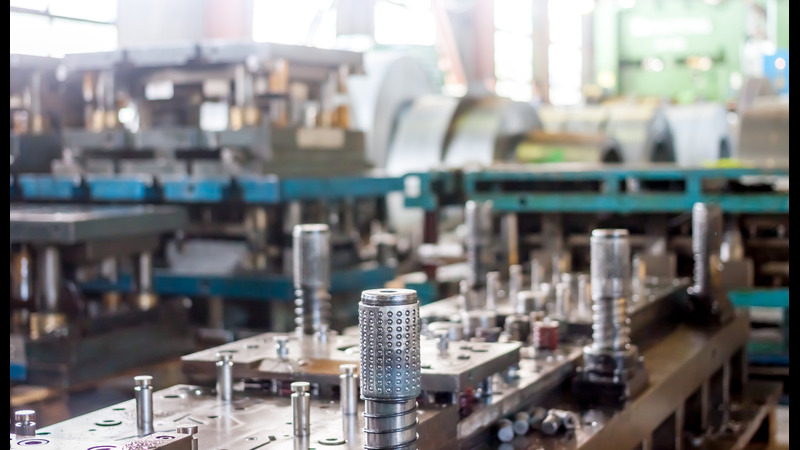

Plastic Injection Molding in California is the process in manufacturing whereby molten plastic is put into a mold to generate specific forms and components. This method’s selection results from its ability to create fast and accurate high numbers of homogeneous and exact components. Three main processes define the process: melting the plastic pellets, inserting them into the mold, and cooling and ejecting the produced product.

Given California’s various economic sectors—including consumer products, aerospace, and automotive—this process is rather crucial there. The Plastics Industry Association’s research indicates that the U.S. plastics sector—including companies based in California—is expected to have a market value of $550 billion by 2026, therefore underlining the growing demand for plastic goods.

The Advantages of Plastic Injection Molding

One advantage is the great efficiency of plastic injection molding. Manufacturing fewer parts and less waste by businesses helps to lower production costs. In California, where running costs could be outrageous, this efficiency is quite important. Moreover, the greatly improved technique under plastic injection molding allows more difficult designs and better-quality finishes.

Furthermore, supporting the California manufacturing industry is a very qualified workforce. Many technological colleges and institutions offering courses in specialized manufacturing and engineering call the state home. This training program ensures qualified employees for California plastic injection molding companies, therefore enhancing production and creativity.

Industry Statistics and Trends

Recent numbers indicate that California’s plastic injection molding industry is anticipated to grow very fast. IBISWorld projects that throughout the next five years, Plastic Injection Molding in California will grow yearly at 3.5%. Growing consumer goods and the need of the automobile industry fuel this development since companies depend more and more on plastic components for their products.

Furthermore, it influences the view of plastic injection molding as an environmental issue. Two green practices among many California companies include beginning recycling programs and employing biodegradable products. This shift not only meets consumer needs for greener goods but also conforms to California’s rigorous environmental regulations.

King Epoxy Emblem Co.: Your Trusted Partner in Plastic Injection Molding

A leading company in the field, King Epoxy Emblem Co., Ltd, is oriented in technology related to excellent Plastic Injection Molding in California. Having years of field experience, the company is quite happy to produce suitable and strong plastic parts for many uses. California companies that decide to use plastic injection molding can rely on them because of their commitment to client satisfaction and creativity. Focusing on sustainability and quality, they are probably going to set the benchmark in this interesting field.